It all starts with some 100 year old douglas fir we salvage from local demolitions

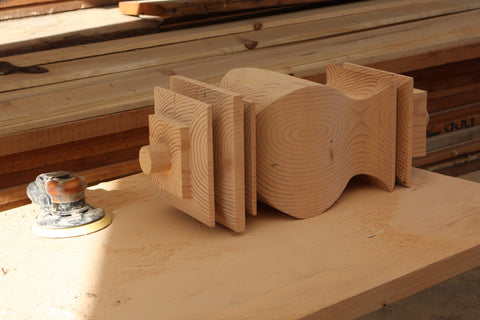

We mill all the lumber into the correct dimensional sizes so we can fabricate all the parts of the table before assembly. These pieces are for the trestle legs and the supports that will hold the leaf extension tracts.

Once the top and bottom of the leg is build its time to glue up the wood block that will become the pedestal

Every piece of furniture we build requires templates so we can reproduce the same design in the future. The pattern in this picture will be traced onto the wood block and then it's off to the band saw

Each block is hand cut and shaped on the bandsaw.

Looking good

Pipe clamps are the work horse of the shop . It takes around 2 hours for the glue to dry so we can proceed to the next step ... assembling the complete table.

Love the way this solid white oak extension trestle table turned out . Going to be a perfect fit for 1920's spanish style home in Glendale

Leave a comment